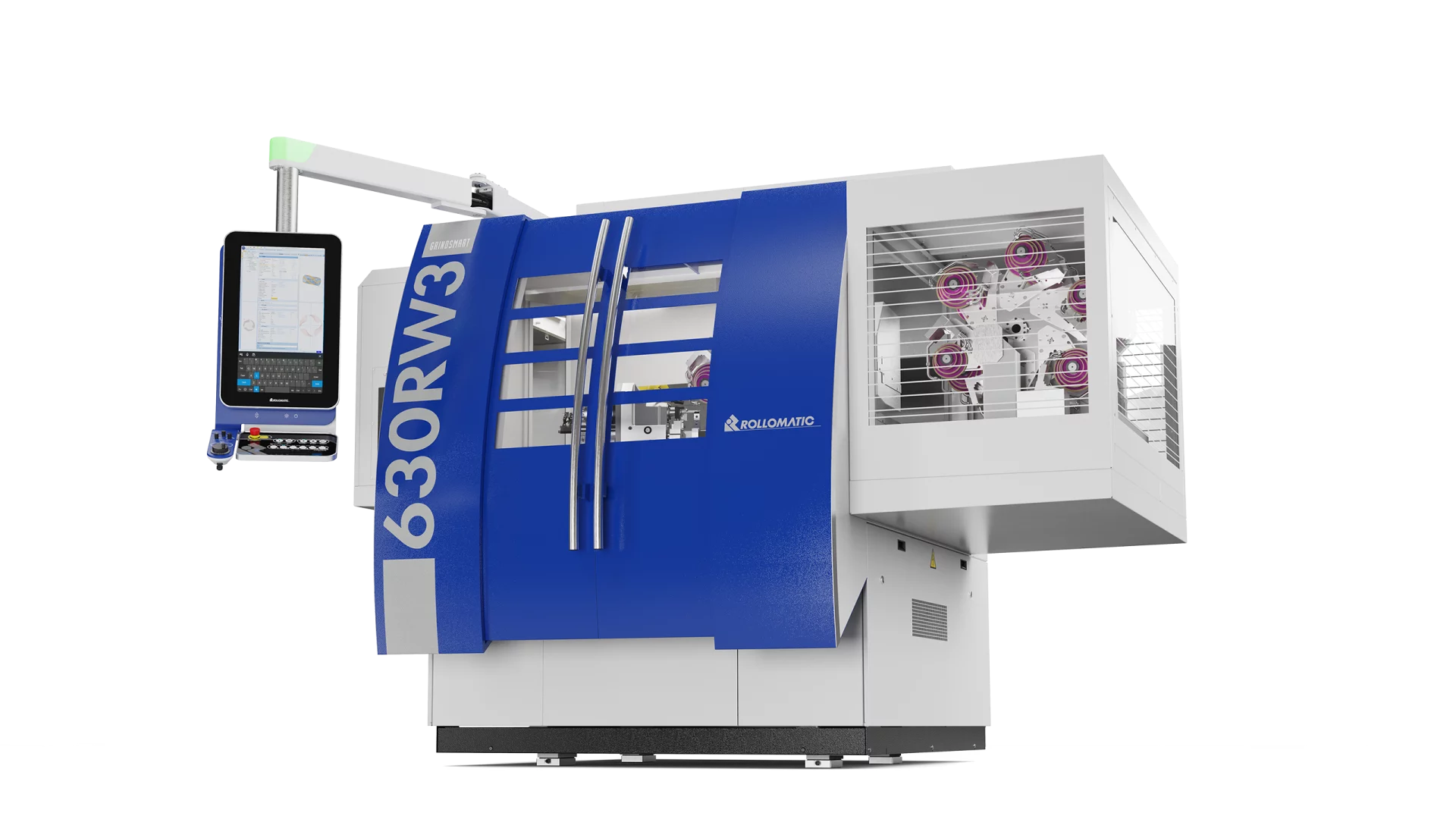

GrindSmart® 630RW3

Download the brochure

Please enter your email address to start downloading the brochure.

To meet the increasing demands of the medtech industries, Rollomatic introduces an evolution of its flagship GrindSmart®630 series, which now incorporates a 6-axis Fanuc robot, offering even greater flexibility and the ability to load tools with up to 500.0 mm overall length.

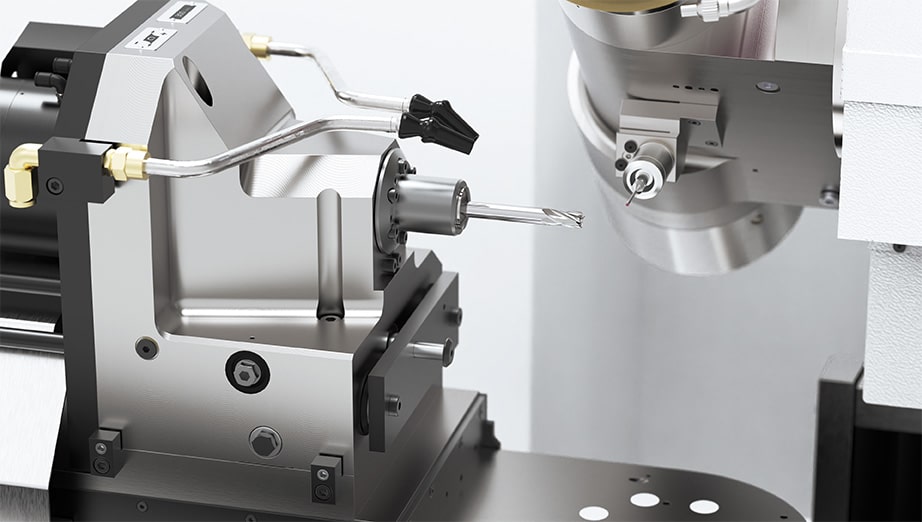

The GrindSmart®630RW3, RW and RS high-precision 6-axis grinding machines are ideal to produce long drills, particularly in the medical sector. Thanks to their innovative kinematic, these new machine models are perfectly adapted to produce a wide variety of applications covering a range of diameters from 0.1 to 20.0 mm, for both large and small production runs.

The GrindSmart® tool grinders range are equipped with linear and rotary torque motors, that provide enhanced surface finish. When combined with the synchronous spindle this technology ensures constant rotation speed, independent of motor load, for uniform surfaces. The use of the same coolant oil for cooling the linear motors and for grinding, enables high-performance production at constant temperature, without additional energy consumption.

Smart Autonomous Grinding

Our goal is to satisfy our customers' demands and increase their competitiveness by constantly improving machining processes. Rollomatic's autonomous grinding concept and machine interface with third-party systems increases the level of production autonomy while maintaining geometric and dimensional tolerances.

Smart Setup Assistant

The Smart Setup Assistant Function was developed with the aim of achieving the first ground tool within the tolerances.

The program generates a grinding path for each operation to be performed on the blank.

These grinding operations are carried out and then measured by the touch probe measuring system, whichdefines the grinding wheel corrections before the first tool is made.

The blank is then ground to the geometry programmed by the operator, taking into account the corrections required to ensure production according to specifications from the first tool.

In-process Measurement

The in-process measurement function ensures that the tool remains within the defined tolerances throughout the production process.

To achieve this, several measurements are made periodically by the touch or laser measurement system to apply the necessary corrections, thus ensuring reliable and unattended production over an extended time.

Advantages

Patented shank guide and steady rest support to reach a concentricity of less than 0.002 mm

Short axis movements for greater stability and precision in production

Linear and torque motors provide mirror surface finish

Small footprint allows optimal use of available shop-floor space

JobManager software for unattended production of tools with different geometries

6-axis kinematics for more flexibility and precision

Enhanced productivity thanks to simultaneous changing of the wheel & nozzle packs during the tool loading/unloading cycle

High-performance synchronous spindle and redesigned HSK50 attachment provide consistent and high quality surface finish

Unique grinding capacity enables production of micro tools and large diameter tools all with the same machine

Smart features

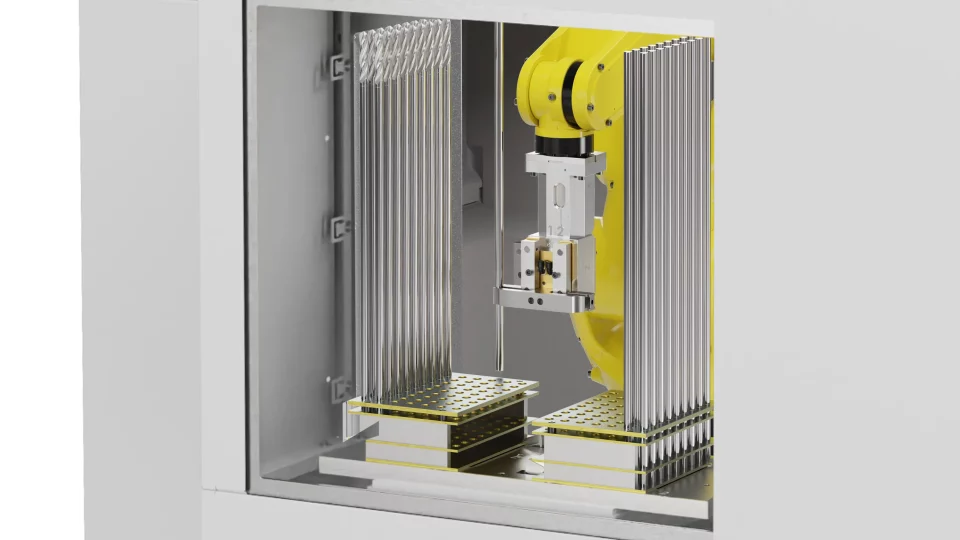

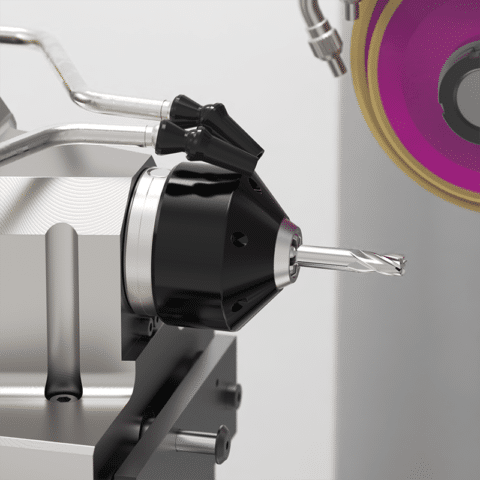

Fanuc Robot

Particularly flexible and able to handle payloads quickly, this compact industrial robot features enhanced reach and the ability to load tools with up to 500.0 mm overall length.- Fast to setup

- Blanks max. overall length of 500mm

- Greater flexibility

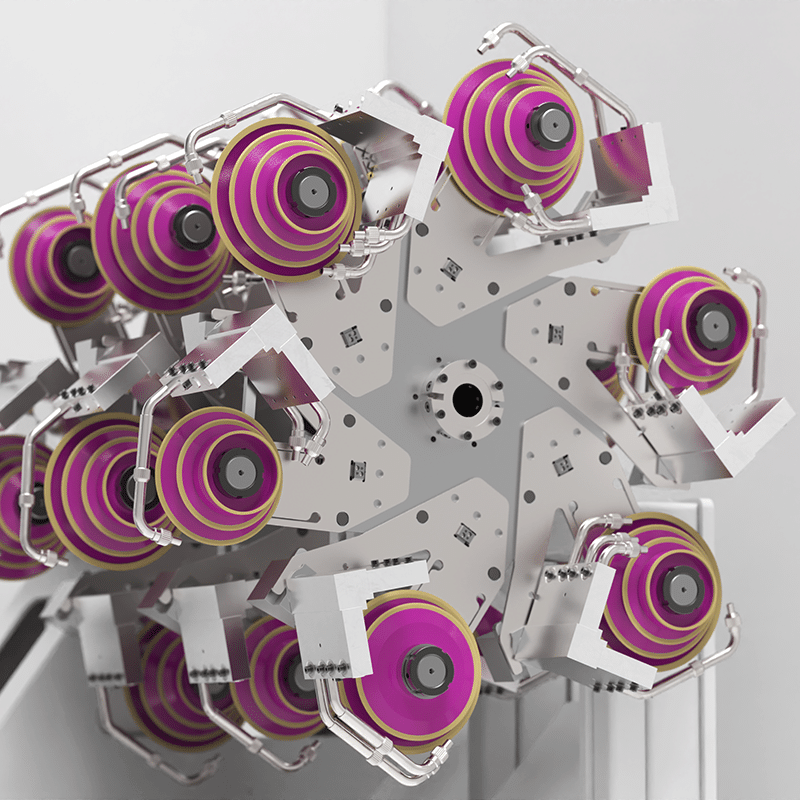

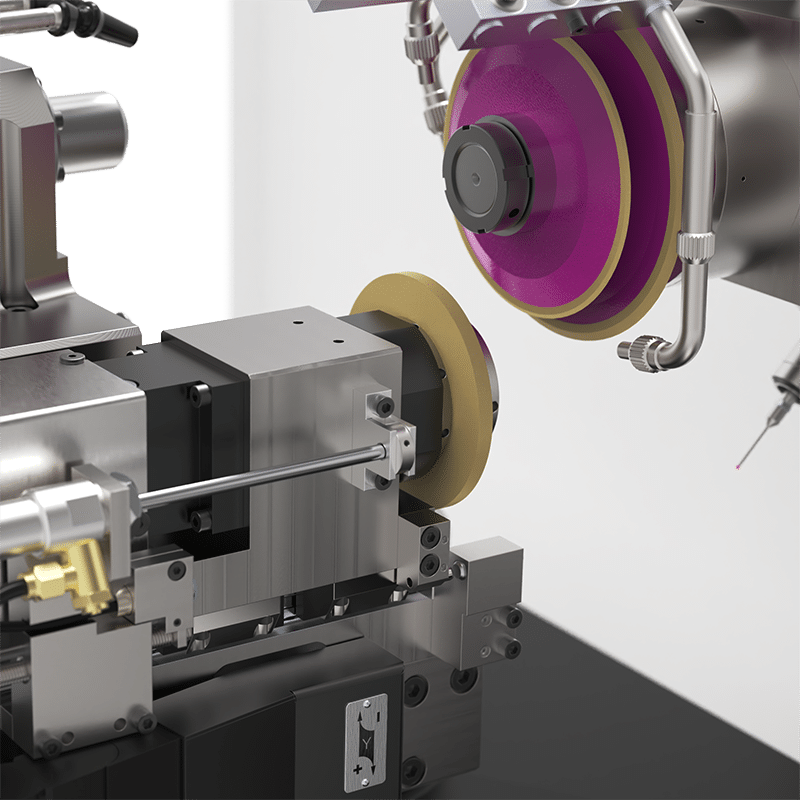

Smart Changer

Smart Changer is an ultra-fast automatic grinding wheel and nozzle changer that offers exceptional flexibility for the production of all types of tools.

The wheel changer can operate simultaneously with the tool loader, which substantially reduces cycle times.

- Increased flexibility

- 16-wheel pack capacity

- Ultra-precise wheel pack change, less than 0.002 mm

- Extended production autonomy

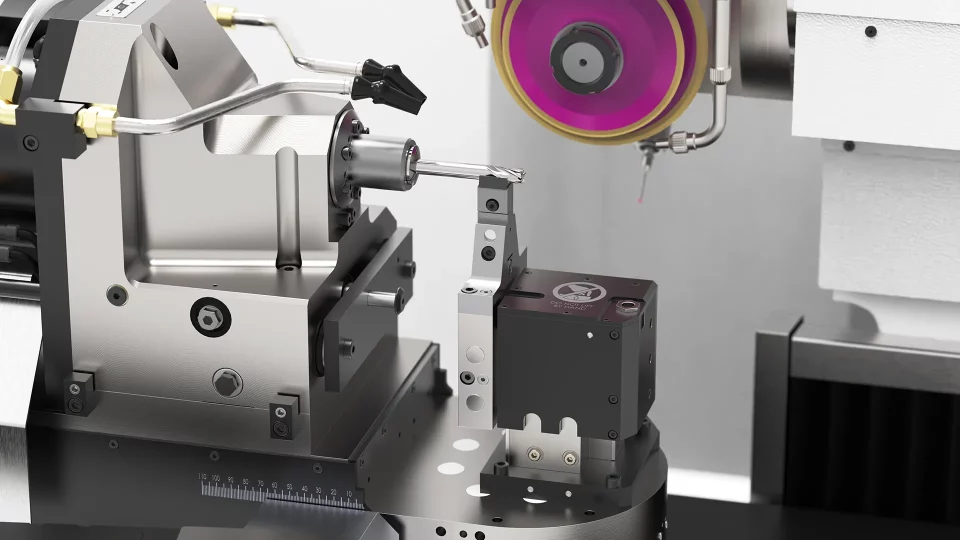

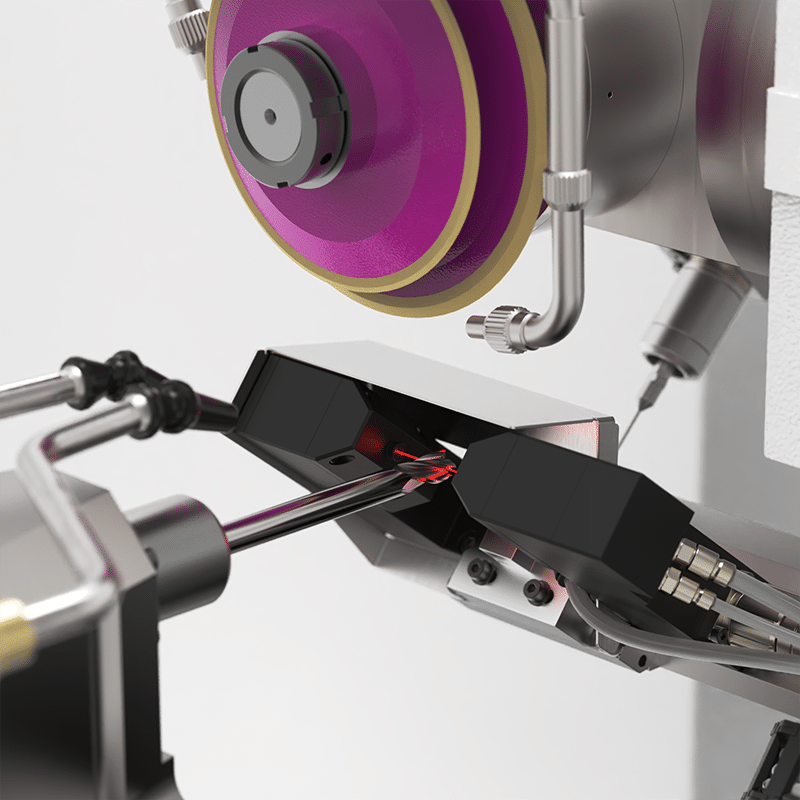

Smart Shank Guide

The Smart Shank Guide is a tool shank guiding system that guarantees concentricity down to a few microns at each clamping. It saves time and boosts productivity, as it is no longer necessary to probe for runout during setup.

- Exceptional concentricity accuracy, less than 0.002 mm at each clamping

- Quick and easy to set up

- Increased productivity

Smart Steady Rest

The Smart Steady Rest is a high precision steady rest for drills and other long tool blank. It provides stability in the grinding process and allows for faster feedrates.

This ensures repetitive quality of the tool throughout the production process.

- Quick and easy to set up

- Highly accurate adjustment system in 3 planes

- Consistent production quality

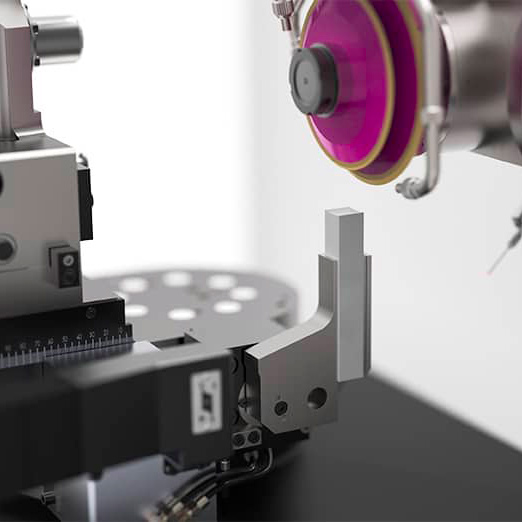

Smart Touch Probe

The Smart Touch Probe is a contact measurement system that allows the blank position to be defined before grinding and avoids variations during production. The system also compensates for machine thermal drift caused by changes in ambient temperature.- Runout compensation and core diameter measurement

- Setting assistance

- Superior stability during the production process

- Elimination of scrap during unattended production

StickSmart®

The StickSmart® is an automatic sticking system for in-process cleaning of grinding wheels. The «stick», mounted in a holder, is used to regenerate superabrasive grinding wheels to maintain their cutting performance.

- Extends the working life of the wheel

- Extends unattended production cycles with high-performance wheels

- Reliable and safe automatic process for the operator

- Efficient, economical and safe solution

Smart in process Wheel Dresser

Smart in process Wheel Dresser is a self-retracting rotary dressing unit driven by a servo motor with a speed of up to 3,000 rpm.

This feature optimizes the service life of the grinding wheels. The maximum dressing wheel diameter is 125 mm for peripheral dressing of diamond and CBN wheels.

- Extended wheel life

- Optimization of production without interruption

- Constant maintenance of the wheel profile

Smart Laser Measurement

The Smart Laser Measurement is a laser measurement unit for in-process inspection and automatic compensation.

This contactless tool measurement option enables reliable, unattended production within tight tolerances, increased productivity, elimination of scrap and cutting-edge damages.

- Wide range of measurable diameters from 0.3 mm to 20 mm

- No need for manual tool measurement during production

- Automatic compensation for tool diameter variations

- Superior stability during the production process

- Elimination of scrap during unattended production

SmartChuck

The SmartChuck is a high-precision, self-centering multi-jaw clamping system that automatically adapts to different diameters without the need for adjustment. The SmartChuck can be used in conjunction with the automatic runout compensation feature included in the VirtualGrind®Pro programming software to ensure optimum concentricity. After a blank has been loaded in the clamping system it is measured with the probe. The measured values are then taken into account when tool paths are calculated, to ensure that the finished tool is produced within the concentricity tolerances of less than 0.005mm.- Clamping range from diameters of 3 to 12 mm

- Clamping concentricity less than 5 μm

- Easy-to-change production diameters, and quick and simple adjustment

Software

VirtualGrind®Pro

VirtualGrind®Pro is the innovative and powerful programming software that comes with Rollomatic GrindSmart® 5- and 6-axis CNC grinding machines.

VirtualGrind®Pro is intuitive, modern, user-friendly and flexible. A perfect combination with Rollomatic precision grinding machines, the user can program and grind all types of high-performance standard or special cutting tools.

Learn moreSmart Connectivity

Industry 4.0 is a constantly evolving world, and management tools have been developed to optimise its productivity. Rollomatic strives to develop connectivity solutions that are compliant with the UMATI standard, facilitating connections between peripherals in production processes and leveraging the available data

Learn moreFor Rollomatic, the process is as important as the machine. To better serve our customers, we are able to provide full turnkeys with every machine.

Turnkey

The turnkey process starts with our Sales Team and their help in defining your project.

Our expert team of Applications Engineers then studies your parts to determine the best machine, options, accessories, peripheral equipment, programs, and training required.

We can also offer Factory Acceptance and Site Acceptance Tests to ensure confidence in the machine and process.

Oil Filtration Systems

Mist Collectors

Balancing Machines

Wheel Presetting Machines

Programming

In Person & Virtual Training

Wheel Dressing & Truing Machines

Grinding Oils

Grinding Wheels

Metrology Equipment

We welcome the opportunity to be a part of your success!

Français

Français Deutsch

Deutsch Italiano

Italiano 简体中文

简体中文